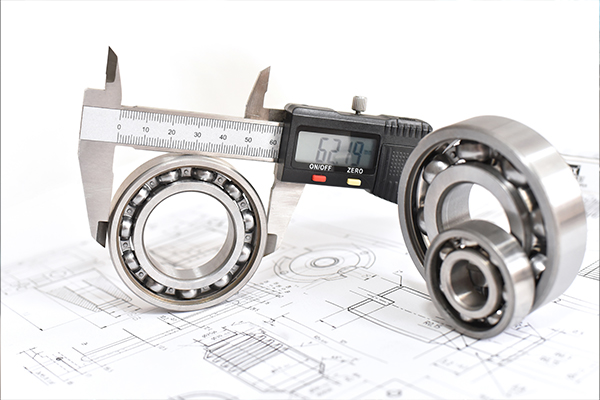

YOUR PRECISION ENGINEERING SUPPORT

Our experience in the engineering and infrastructure industry gives us a genuine insight into our customers problems and we know how costly poor scope engineering, lack of risk understanding, lost operational time, wasted management time, pressure and stress can be.

- Product scope development

- Design

- Research and development

- Innovation

- Replication of old or worn parts

- Refurbishment

- Site support

- Expert advice

- Fast turnaround on shutdowns

- Bespoke and short runs

- Electroplating

- CNC

OUR CAPABILITIES

Predominately our capabilities are:

- Milling

- Turning

- CNC – Small Turning Capabilities

If you have a Precision Engineering Project you’d like to discuss with us, give us a call today for a no obligation quotation.

OUR ENGINEERING MACHINERY

Dean Smith & Grace Type 30 x 168” Centre Lathe

- Swing over bed – 810mm

- Swing over cross slide – 550mm

- Between centres – 4267mm

- Spindle bore – 117mm

- 762mm diameter 4 jaw chuck

Dean Smith & Grace Type 21 x 72” Centre Lathe

- Swing over bed – 590mm

- Swing over cross slide – 335mm

- Between centres – 1828mm

- Spindle bore – 90mm

- 558mm diameter 4 jaw chuck

- Equipped with 2 axis DRO

Colchester Master 2500 Centre Lathe

- Swing over bed – 335mm

- Swing over cross slide – 200mm

- Swing in gap bed – 470mm

- Between centres – 1015mm

- Spindle bore – 40mm

- Equipped with 2 axis DRO

Bridgeport Vertical Mill Series 1

- Table size – 9” x 36”

- X axis travel – 22” with power feed

- Y axis travel – 12”

- Z axis travel (knee) – 16”

- Quill travel – 5”

- Spindle taper – R8

- Equipped with 2 axis DRO

Kearney & Trecker Model 415 S15 Vertical Mill

- Table size – 15” x 76”

- X axis travel – 44”

- Y axis travel – 14”

- Z axis travel (knee) – 14”

- Power down feed to head – 6” travel

- Power feeds & rapids to all table motions

- Equipped with 3 axis DRO

Addison Bandsaw

- Round bar capacity – 254mm

- Rectangular bar capacity – 406mm x 254mm